The Types of Mylar Packaging: A Comprehensive Guide

From coffee beans and herbs to supplements and emergency provisions, Mylar packaging delivers dependable protection, extended shelf life, and a polished, retail-ready look. This guide explains the types of Mylar packaging, how they’re constructed, and where each format excels, so you can confidently match a solution to your product and supply chain. You’ll learn what Mylar packaging is, the primary formats available from Packaging Studio, common use cases by industry, the benefits you can expect, and practical tips for selecting the right size, thickness, and features. Throughout, we reference our range of Mylar bags, stand-up pouches, and custom-printed options designed to help brands grow with consistent quality and performance. Let’s begin with the fundamentals that make Mylar such a versatile packaging material and clarify what is Mylar as well as what is a Mylar bag in practical terms. For readers comparing options, we’ll repeatedly reference the types of Mylar packaging and the most common uses of Mylar across industries.

Table of Contents

What Is Mylar Packaging?

Mylar packaging refers to flexible packages made from biaxially oriented polyethylene terephthalate (BoPET), a polyester film prized for its strength, clarity, and barrier performance. If you’ve ever wondered “what is Mylar” or “what is a Mylar bag,” this is the foundation: a high-performance polyester film often laminated for added protection.

These mechanical and barrier characteristics are well-documented in academic research. A review titled Polyethylene terephthalate (PET) in the packaging industry on ScienceDirect outlines how biaxial orientation enhances PET’s tensile strength, dimensional stability, and gas barrier properties key reasons it forms the base of modern Mylar packaging films.

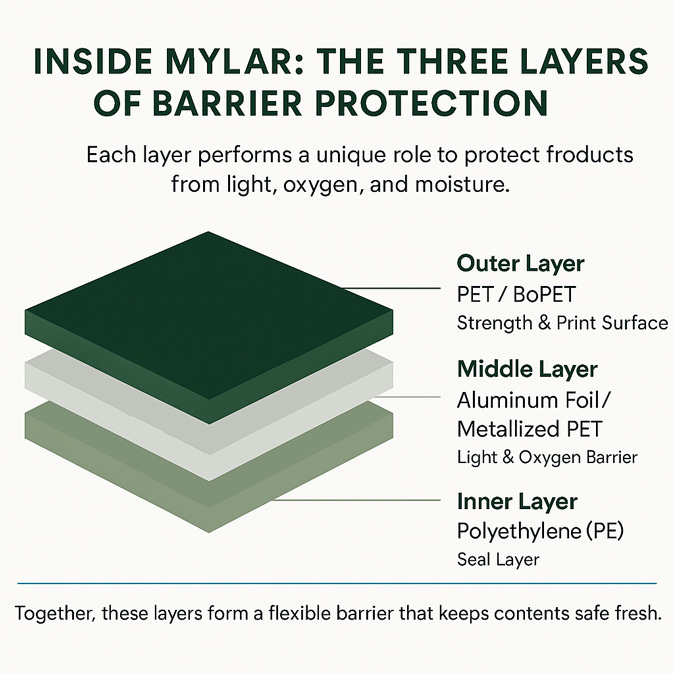

In many applications, Mylar is laminated with other layers such as aluminum foil for light blocking or polyethylene for sealability to improve resistance to oxygen, moisture, and punctures. This multi-layer structure enables Packaging Studio to supply bags, pouches, and rollstock that safeguard aroma, freshness, and product integrity across categories including snacks, coffee, supplements, and sensitive dry goods.

Mylar emerged in the 1950s with advances in polyester chemistry and film orientation. By stretching the film in two directions, manufacturers aligned polymer chains, which improved tensile strength, dimensional stability, and barrier properties. Over time, innovations in coating, metallization, and lamination produced high-performance structures that reliably extend shelf life and reduce waste. These improvements underpin today’s Mylar solutions, which balance protection, printability, and ease of sealing.

Packaging Studio leverages these proven technologies in formats suitable for both small-batch brands and high-volume operations, ensuring consistent results from pilot runs to national rollouts. Understanding what is Mylar helps clarify why the types of Mylar packaging perform so well across varied supply chains.

Several qualities make Mylar ideal for packaging. Its barrier performance helps limit oxygen and moisture exposure while controlling UV and light transmission critical for preserving flavor, potency, and color. Its toughness and puncture resistance reduce pinholes and tears during filling, shipping, and retail handling. Dimensional stability supports crisp graphics, reliable heat seals, and clean seams, which translate to professional presentation and dependable closure integrity. Mylar laminates can also be tailored with features such as resealable zippers, child-resistant closures, and clear windows, all without compromising protection. At Packaging Studio, our Mylar solutions are engineered to these standards, delivering a premium look and feel alongside the functional protection your product requires. In short, when people ask “what is a Mylar pouch” or “what is a Mylar package,” the answer ties back to these engineered barrier and usability advantages and the many uses of Mylar in real-world applications.

Different Types of Mylar Packaging

Standard Mylar Bags and Their Features: Our standard Mylar bags are composed of high-barrier films designed to protect contents from oxygen, moisture, and light three primary threats to product freshness and shelf life. Available in commonly used sizes and gauges, these bags include heat-sealable tops for airtight closure, optional zippers for resealability, and puncture-resistant construction for storage and transit. Whether you package pantry foods, nutraceuticals, or artisanal goods, Packaging Studio’s standard Mylar bags deliver consistent performance with a clean, professional appearance suitable for both retail shelves and direct-to-consumer shipments. Among the types of Mylar packaging, these are the most versatile and represent some of the most common uses of Mylar in everyday products.

Stand-Up Pouches: Stand-up pouches are gusseted at the bottom to provide stability and shelf presence while maintaining robust barrier protection. They are ideal for products that benefit from upright display coffee, snacks, powdered supplements, teas, and dried foods. Options include zip closures for convenient access, tear notches for easy opening, and hang holes for peg displays. With custom printing, matte or gloss finishes, and clear windows, stand-up pouches offer a blend of merchandising appeal and functional convenience, another example that helps illustrate what is a Mylar pouch within the broader set of the types of Mylar packaging.

Flat Pouches and Sachets: Flat pouches are streamlined, low-profile formats perfect for single serves, sample packs, and lightweight items. These pouches use less material than gusseted bags yet maintain excellent barrier performance. Flat sachets are frequently chosen for powdered drink mixes, seasoning blends, and trial sizes. They seal cleanly, pack efficiently for e-commerce, and can include tear notches, batch coding, and easy-open features. When speed and cost-effectiveness are important, flat pouches provide a practical solution without compromising protection. These formats highlight everyday uses of Mylar where slim form factors and high barriers are required.

Gusseted Bags: Side-gusseted bags expand to accommodate larger or bulk quantities while maintaining a compact footprint for storage and shipping. These bags are popular for coffee, grains, rice, and bulk dry goods. Options include one-way degassing valves for freshly roasted coffee, high-barrier laminations to block oxygen and moisture, and metallized films to reduce light exposure. Their form factor allows efficient stacking and palletization, making them well suited for warehouse operations and retail back-of-house storage. For anyone researching what is Mylar used for in bulk formats, gusseted bags are a leading choice within the types of Mylar packaging.

Custom-Printed Mylar Packaging: Packaging Studio’s custom-printed Mylar solutions let you bring your brand to life. Choose vibrant full-color artwork, matte or glossy finishes, and optional windows that showcase your product while maintaining barrier integrity. Our team supports dielines, compliance copy, and layout for stand-up pouches, flat pouches, and gusseted formats. Minimum order quantities are tailored to growing brands, and color management safeguards consistency across production runs. Add practical features tear notches, hang holes, batch codes, and scannable markings to streamline fulfillment and enhance shelf presence. These tailored options span the types of Mylar packaging and address diverse uses of Mylar from boutique launches to national programs.

Child-Resistant Mylar Bags: For products requiring heightened safety, we offer certified child-resistant Mylar bags that meet stringent regulatory standards. These pouches integrate secure mechanisms such as certified press-to-close or slider systems while preserving barrier performance for aroma, potency, and freshness. They are suited to items that must be kept out of reach of children, delivering safety without compromising design or usability. Choose customizable sizes, print options, and compliance labeling support to align your child-resistant packaging with both regulatory requirements and your brand aesthetics. If you’re evaluating what is a Mylar solution for regulated goods, this category is essential.

Anti-Static and ESD-Safe Mylar: Sensitive electronics benefit from Mylar formats designed to manage static charge and moisture. Our ESD-safe pouches incorporate anti-static coatings or metallized layers that shield components from static discharge, dust, and humidity. These bags can be paired with serialized labels, lot tracking, and barcodes to support quality assurance workflows. With strong seams and puncture-resistant structures, ESD-safe Mylar helps protect PCBs, cables, sensors, and assemblies throughout storage and transit. This is one of the specialised uses of Mylar that demonstrates how the types of Mylar packaging extend beyond food and consumer goods.

Applications of Mylar Packaging

Food Storage and Pantry Goods: Mylar is widely used for food because it offers an exceptional barrier against oxygen, moisture, and light, the leading contributors to spoilage. For pantry staples like rice, beans, flour, coffee, and dehydrated meals, heat-sealable Mylar bags paired with proper oxygen control can help maintain freshness and extend shelf life. At packagingstudio.com, our food-grade options are available in various thicknesses for durability and puncture resistance, with features like clear windows and date labels to simplify inventory rotation. Tear notches and zip closures add convenience for everyday use, while metallized films protect light-sensitive ingredients. These are classic uses of Mylar and illustrate what is Mylar valued for in household and commercial kitchens.

Coffee and Specialty Foods: Freshly roasted coffee off-gasses CO2, which can inflate or rupture sealed packages if not properly vented. Mylar pouches can be equipped with one-way degassing valves that allow CO2 to escape while preventing oxygen ingress. High-barrier laminations help preserve flavor, aroma, and oils, and opaque finishes reduce UV exposure that can degrade coffee quality. Specialty foods, spices, teas, dried fruit, and artisan snacks likewise benefit from tailored barrier control and premium finishes that support shelf appeal. For anyone asking “what is a Mylar coffee bag,” this category shows how the types of Mylar packaging are engineered for off-gassing and freshness.

Cannabis and Regulated Markets: In regulated industries, product integrity and compliance are paramount. Mylar packaging supports potency preservation by limiting exposure to air and UV light, which helps maintain terpene profiles and aroma. Child-resistant closures, tamper-evident features, and odor-control layers are common components that meet regulatory expectations while protecting brand reputation. Our compliant-ready Mylar solutions accommodate state-specific labeling, batch identification, and track-and-trace needs, and custom print areas allow premium branding without compromising safety. These applications underscore the specialised uses of Mylar in compliance-driven markets.

Nutraceuticals and Personal Care: Supplements, vitamins, and powdered mixes require reliable barrier protection to maintain efficacy and flavor. Mylar’s oxygen and moisture resistance helps prevent clumping and degradation. For cosmetics and personal care items such as bath salts, masks, and single-use treatments custom finishes and windows deliver a refined presentation while the film structure safeguards product integrity. Resealable closures support multi-use products and clean storage. Understanding what Mylar is in this context highlights its role in protecting activities and enhancing presentation.

Electronics and Precision Components: Mylar’s robust barrier properties, paired with optional anti-static features, make it a strong choice for protecting circuits, cables, and precision assemblies. Static discharge, dust, and humidity can damage sensitive components; specialized Mylar bags mitigate these risks during storage and shipping. At packagingstudio.com, you’ll find ESD-safe options that combine moisture barrier performance with static shielding for PCBs and assemblies. With heat seals, serialized labeling, and lot tracking, these formats support quality assurance while reducing the chance of contamination or transit damage, further proof of the wide-ranging uses of Mylar beyond food and consumer goods.

Benefits of Using Mylar Packaging

Mylar packaging is trusted across industries because it consistently preserves product quality and extends shelf life. The film’s barrier layers, durable construction, and optional light-blocking features work together to protect contents from environmental stressors. At packagingstudio.com, our Mylar pouches and bags are engineered for repeatable performance, whether you need retail-ready presentation or rugged protection for e-commerce and logistics. Knowing what Mylar is and how the types of Mylar packaging are tuned for different needs helps teams select solutions confidently.

Moisture and Oxygen Barrier: Mylar’s multi-layer film creates a formidable shield against moisture ingress and oxygen transmission, helping prevent staleness, rancidity, clumping, and microbial growth. For foods and nutraceuticals, barrier control is essential for flavor, texture, and efficacy. Combined with high-quality heat seals and optional zip closures, products maintain their intended freshness from filling to end use. Selecting the appropriate barrier grade (often measured via oxygen transmission rate and water vapor transmission rate) helps ensure long-term stability and aligns with the best uses of Mylar for your category.

Durability and Puncture Resistance: The tensile strength of Mylar resists tears, abrasions, and punctures during filling, shipping, and retail handling. Durable pouches reduce product loss and returns, and they preserve barrier integrity over time. Packaging Studio offers a range of film thicknesses to match your handling demands from lighter gauges for single-serve packs to heavy-duty laminations for bulk formats or sharp-edged contents. Reinforced seams and robust seal areas further enhance performance in demanding environments.

Light-Blocking and UV Protection: Light exposure accelerates oxidation, fades colors, and reduces active ingredients in sensitive products. Mylar structures can be laminated with opaque layers or metallized films to significantly reduce light transmission. At packagingstudio.com, you can select matte black, metallized, or custom-printed opaque finishes to protect light-sensitive goods such as coffee, spices, teas, and supplements. These finishes combine function with a premium aesthetic that elevates shelf appeal.

Printability and Presentation: Mylar’s dimensional stability supports high-definition printing and precise registration for branded packaging. Crisp graphics, color fidelity, and clean finishes help your product stand out while conveying quality and care. With custom dielines and finishes, you can tailor both the look and functionality of your packaging to your merchandising strategy, from minimalist designs to bold, full-bleed artwork.

Versatility and Feature Integration: Mylar laminates can be engineered with features such as resealable zippers, child-resistant mechanisms, hang holes, tear notches, and clear windows all integrated without compromising barrier performance. For coffee and other off-gassing products, one-way valves manage internal pressure while maintaining oxygen control. This feature-rich approach ensures packaging supports both user experience and operational needs and reflects the diversity within the types of Mylar packaging.

Choosing the Right Mylar Packaging

Selecting the right Mylar packaging starts with aligning material properties to your product’s shelf-life, compliance, and merchandising goals. Consider oxygen and moisture transmission rates, light-blocking requirements, puncture resistance, and heat-seal compatibility. Different categories food, supplements, coffee, cosmetics, electronics have distinct sensitivities to air, humidity, and UV. Matching a suitable barrier grade helps preserve freshness, potency, and visual appeal. If your supply chain includes e-commerce or long-distance shipping, choose constructions that balance toughness with weight, controlling freight costs without compromising protection. As you evaluate the types of Mylar packaging, keep a checklist of the key uses of Mylar for your product so the final spec fits real-world conditions.

Size and Thickness: The pouch size should match your product volume to minimize trapped air and headspace, which can impact shelf life and presentation. Thicker films (commonly 4–7 mil equivalents) provide greater puncture resistance for heavy, sharp, or bulk contents. Lighter gauges are ideal for samples, single-serve formats, and products with lower impact risk. Plan dimensions to accommodate seal areas, tear notches, zippers, and valves, ensuring the filled package maintains both form and function. Packaging Studio’s range of sizes and film structures helps you dial in protection without over-packaging.

Closure and Access Features: Choose closures that fit the product and user experience. Heat-seal tops create airtight primary seals; resealable zippers support multi-use convenience. Child-resistant closures may be required for regulated products, and tamper-evident features enhance trust. Hang holes support point-of-purchase displays, while tear notches improve ease of opening. For coffee, one-way degassing valves are a must; for electronics, consider anti-static or ESD-safe materials. These choices clarify what is a Mylar solution tailored to your category.

Material and Finish Selection: Opaque and metallized laminations reduce light exposure for sensitive products, while clear windows showcase quality and texture. Matte finishes provide a refined look; gloss finishes enhance vibrancy. If sustainability is a priority, ask about structures that incorporate recyclable or post-consumer recycled content. Our team can help you compare barrier performance, finish options, and regulatory considerations for your product category, grounding recommendations in what is Mylar capable of within modern laminations.

Customization and Compliance: Packaging Studio offers custom printing with full-color graphics, matte or gloss finishes, and metallic accents that strengthen brand identity. We provide guidance on artwork preparation, dielines, and compliance copy, including ingredient panels, warnings, and state-specific requirements. For regulated markets, we support batch identification, variable data printing, and track-and-trace integration to keep your packaging compliant and production-ready.

Conclusion and Final Thoughts

Mylar packaging stands out for its combination of barrier protection, durability, and flexibility across a wide spectrum of applications. From preserving aroma and freshness to resisting punctures and moisture, the key types of Mylar packaging deliver reliable performance in storage, retail, and shipping environments. Lightweight, heat-sealable formats simplify packing and reduce transportation costs, while resealable features and well-designed closures enhance the user experience. For brands focused on shelf appeal, premium finishes and window options provide strong visual impact without sacrificing protection. These advantages reflect the core definition of what is Mylar in packaging and why the uses of Mylar continue to expand.

Looking ahead, Mylar technologies continue to evolve for improved functionality and sustainability. Expect progress in recyclable and post-consumer recycled content structures, integrated indicators for oxygen and moisture, and precise barrier layering tailored to product-specific needs. Advances in closure systems will expand options for child resistance and tamper evidence, while high-definition printing will deliver more intricate graphics. As regulations and consumer expectations change, Mylar packaging will adapt with materials and methods that minimize waste and maximize product safety further broadening the types of Mylar packaging and the practical uses of Mylar.

If you’re ready to explore how Mylar can elevate your product line, Packaging Studio is here to help. Browse our curated selection of Mylar bags, stand-up pouches, and customizable formats to find the right barrier level, size, and closure for your application. Our team will guide you through print options, compliance requirements, and production timelines to ensure a smooth rollout. Visit packagingstudio.com to compare the types of Mylar packaging we offer, request samples, or start a custom project that aligns with your brand and operational goals. If you still have questions about what is a Mylar pouch or what is Mylar in general, our specialists can provide side-by-side comparisons to make your decision easy.